Idle Relearn (aka throttle body relearn) is the procedure that is required to obtain the correct idle speed after replacing electronic throttle body, disconnecting a battery cable, clearing a check engine light, etc. The symptoms are, idle is too low, too high, or erratic. Sometimes the engine stalls when you stop at the traffic light. And you may see the check engine light come on with the idle speed related trouble codes.

Why does Idle Relearn need?

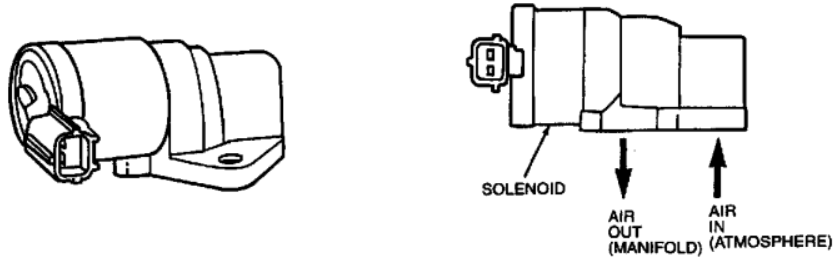

Many newer vehicles use an electronic throttle body which contains a throttle plate, motor, and sensors. They are responsible for regulating all air flow into the engine, including the air flow for maintaining idle speed. When idling, the vehicles computer sends a signal to the throttle body and controls the throttle plate to adjust the idle speed depending on the engine temperature and whether AC is on or off. When the computer loses the connection to the throttle body, it loses the position of the throttle plate. Thus, the vehicle computer needs to relearn the throttle plate after losing connection to it.

When is Idle Relearn required?

As mentioned above, Idle Relearn is required when the vehicle computer loses the connection to a throttle body. And, many things cause it to happen.

- Disconnecting a battery cable

- A battery dies

- Replacing a battery

- Clearing the check engine light

- Replace an electronic throttle body

- Cleaning an electronic throttle body in an inappropriate way

- etc…

Please note that it doesn’t mean that you will need the idle relearn after these repairs or incidents. It totally depends on models of vehicles.

Read Also: How to clean the Throttle Body?

Does my car need Idle Relearn?

In general, the procedure of idle relearn is necessary on vehicles with electronic throttle body (=ETB aka DBW Drive-By-Wire).

How does Electronic Throttle Body work?

Vehicles with ETB don’t have a physical cable connected between a throttle body and accelerator pedal. It’s fully controlled by electricity. There is a sensor attached to accelerator pedal that tells the vehicle computer how deeply you press the pedal. And, the computer sends a signal to a motor inside ETB and make the throttle plate open or close. When idling, the computer sends a signal to open the throttle plate slightly, so the engine keeps running without stalling.

How does a conventional throttle body work?

A conventional throttle body is simple. When you press an accelerator pedal, a cable that physically connects the accelerator pedal with throttle body pulls and turn to open the throttle plate. When you release, a spring turns back and closes the throttle plate. So, a conventional throttle body has another device to control the idle speed. It’s called the Idle Air Control Valve (IAC valve). The IAC valve is fitted over the throttle body, and it bypasses an air over the throttle plate. The computer sends a signal to the IAC valve and controls the air flow to maintain the idle speed. IAC valves need a procedure to initialize, too. The procedures are a lot simpler, though. For examples, leaving the key on for a few minutes or letting it idle without any load for several minutes.

The point is that ETB is a much more complicated component than conventional throttle body. IAC valve is just an electric motor and used only for adjusting the idle speed. ETB, on the other hand, is responsible for not only maintaining the idle speed but also responding to the accelerator pedal. It communicates with the computer all the time. Thus a set of procedure to have the computer relearn is necessary after a certain repair or disconnecting a battery, etc.

How can you get the procedure of idle relearn?

Unfortunately, not all repair manuals have the information about idle relearn. And you may or may not find it in the owner’s manuals. So where can you find it? Go online, search “idle relearn + make, model, and year of your vehicle,” and you may get results. If not, search “idle relearn + make” only. The procedure may be the same among all vehicles from the same manufacturer.